Enamel Reactor Kettle / Lined Glass Reactor Kettle

Application

Application Working principle

Working principle Introduction

Introduction

Characteristic

- Anchor style, frame style,

- Oar style and turbo style.

- Cycloid needle-wheel adapted

- Nip-sheath sealing, steam-heating, electric heating

- And conducting heat oil to meet the technology

- It is customizing according to ur requirements

Power Supply: 380V, 50/60Hz(Can be customized)

Materials; The part contacting with materials is SS304 or SS

Seal: Dual End Mechanical Seal (Pressure Balance Device is optional.

Technical parameter

|

Nominal Capacity(L) |

Actual capacity(L) |

Electric Power |

Jacket volume |

Inside pot size |

Outer pot size(φmm) |

Reducer Model |

motor(n/kw) |

speed |

|

50L |

61L |

3×2 |

95L |

400 |

600 |

m3 |

1450/0.6 |

60-80 |

|

100L |

120L |

6×2 |

120L |

500 |

700 |

m3 |

1450/0.6 |

60-80 |

|

200L |

247L |

6×3 |

200L |

600 |

800 |

m4 |

1450/1.5 |

60-80 |

|

300L |

355L |

6×3 |

250L |

700 |

900 |

m4 |

1450/1.5 |

60-80 |

|

500L |

589L |

9×4 |

290L |

900 |

1100 |

m6 |

1450/2.2 |

60-80 |

|

1000L |

1215L |

12×4 |

560L |

1200 |

1400 |

m8 |

1450/4 |

60-80 |

|

2000L |

2244L |

15×5 |

750L |

1400 |

1600 |

m8 |

1450/4 |

60-80 |

|

3000L |

3201L |

15×5 |

1015L |

1600 |

1800 |

m8 |

1450/7.5 |

60-80 |

|

4000L |

4020L |

15×5 |

1226L |

1600 |

1800 |

m10 |

1450/7.5 |

60-80 |

|

5000L |

5170L |

18×5 |

1400L |

1800 |

2000 |

m10 |

1450/7.5 |

60-80 |

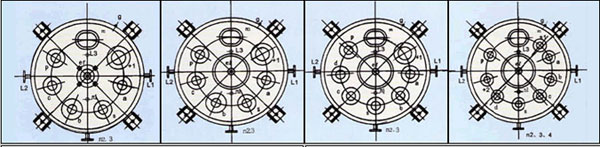

(搪瓷反應(yīng)釜/搪玻璃反應(yīng)釜結(jié)構(gòu)圖)